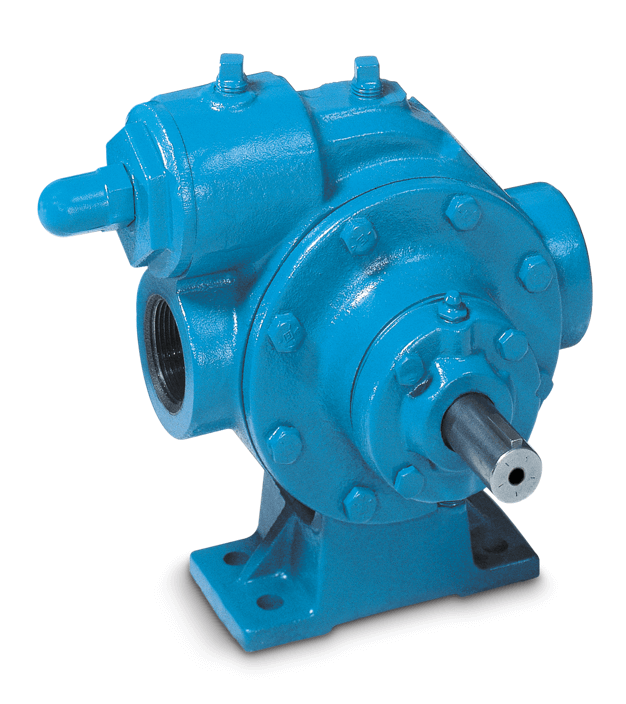

Sliding Vane Pumps

LG1 Pumps

Motor Speed Pump for Single Cylinder Filling

- Pumps are equipped with 1-in. NPT tapped parts and use an exclusive “combination” valve that acts as both a back-to-tank bypass valve and an internal safety valve (no separate bypass valve is needed).

- C-face or bracket mount option with direct motor drive

- Max flow rate 13 gpm (49.2 L/min)

- Max differential pressure 125 psi (8.6 bar)

- Self-priming, high suction capabilities enable line stripping

- Self-adjusting vanes keep performance consistency high

- UL listed

- Equipped with replaceable casing liner, end discs, and vanes

- Applications:

- Cylinder filling

- Motor fueling

- Small vaporizers

- Dispensers

LG1 Brochure

Sliding Vane Diagram

Sliding Vane Benefits

Sliding Vane Cavitation Liner

Dispenser Applications

Sliding Vane Action Video

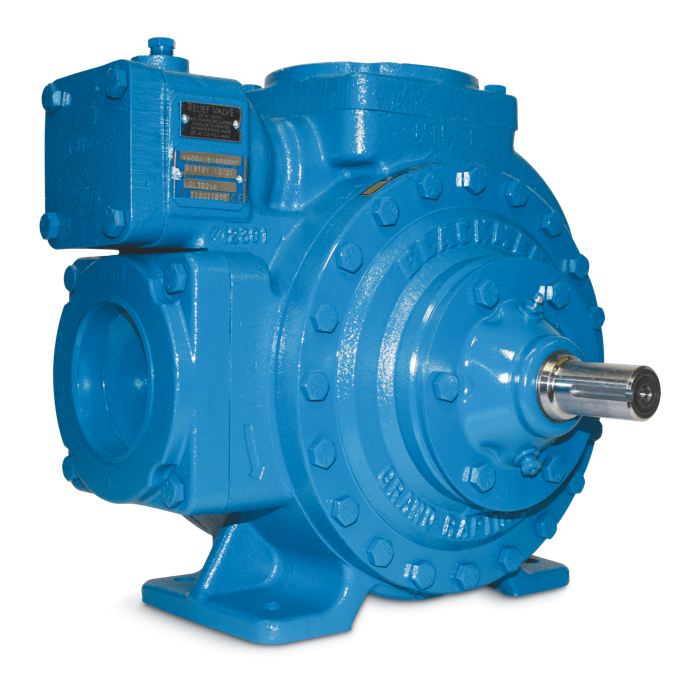

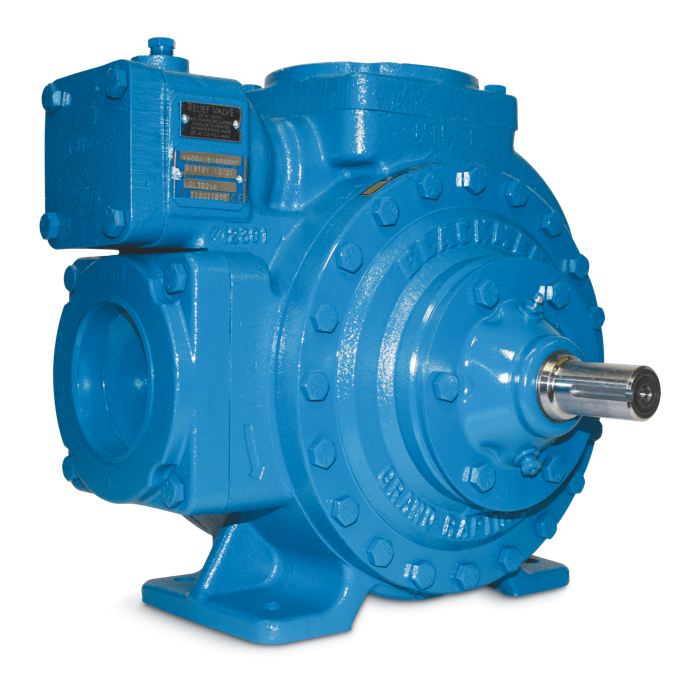

Sliding Vane Pumps

LGL 1.25 - 1.5 Series

Motor Speed Pumps for Motor Fueling and Multi-Cylinder Filling

- Available in 1.25 and 1.5 inch models

- Equipped with internal relief valve

- Flange mounted or foot mounted with direct motor drive

- Max flow rate 33 gpm (125 L/min)

- Max differential pressure 150 psi (10.3 bar)

- Self-priming, high suction capabilities enable line stripping

- Self-adjusting vanes keep performance consistency high

- UL listed

- Equipped with replaceable suppression liner, end discs, and vanes

- Applications:

- Motor fueling

- Multiple-station cylinder filling

- Variety of small transfer jobs

LGL 1.25 & 1.5 Brochure

Sliding Vane Diagram

Sliding Vane Benefits

Sliding Vane Cavitation Liner

Sliding Vane Action Video

Sliding Vane Pumps

TLGLF Series

Multi-Purpose Pumps for Bulk Mobile LPG Applications

- 3 Available Models – 3-inch TLGLF3 and TLGLF3HD, and 4-inch TLGLF4

- Equipped with double-ended drive shaft for clockwise or counter-clockwise rotation

- Auxiliary intake port for emergency unloading of another tank or transport

- Flange-mount directly to a commercial internal control valve, in combination with the tank of a bobtail or transport

- PTO or hydraulic drive packages available

- Max flow rate of 350 gpm (1,325 L/min) for the TLGLF4. The TLGLF3HD has a max flow rate of 201 gpm (761 L/min) which is 55% greater than the 129 gpm (488 L/min) flow rate of the TLGLF3

- Max differential pressure is 125 psi (8.62 bar)

- Self-priming, high suction capabilities enable line stripping

- Self-adjusting vanes keep performance consistency high

- UL listed

- Equipped with replaceable cavitation suppression liner, end discs, and vanes

- Standard cavitation suppression liner reduces noise, vibration and harmful effects of cavitation

- Applications:

- Mounted to bobtail and transport trucks

TLGLF Brochure

Sliding Vane Diagram

Sliding Vane Benefits

Sliding Vane Cavitation Liner

Transport Applications

Sliding Vane Action Video

Sliding Vane Pumps

LGL 2 - 4 Pumps

Multi-Purpose Pumps for Bulk Plants, Terminals, and Truck Systems

- Pumps come in 2, 3, and 4 inch models

- Single or double-ended drive shaft available

- Available as truck mounted pumps driven by P.T.O or hydraulic drive system or standard based mounted V-bet or Helical Gear Reduction Drive

- Max flow rate 350 gpm (1,325 L/min)

- Max differential pressure 150 psi (10.34 bar)

- Self-priming, high suction capabilities enable line stripping

- Self-adjusting vanes keep performance consistency high

- UL listed

- Equipped with replaceable cavitation suppression liner, end discs, and vanes

- Standard cavitation suppression liner reduces noise, vibration and harmful effects of cavitation

- Applications:

- Bulk plant service

- Multiple cylinder filling

- Vaporizers

- Bobtail and transport loading and off-loading

LGL 2 - 4 Brochure

Sliding Vane Diagram

Sliding Vane Benefits

Sliding Vane Cavitation Liner

Bulk Plant Applications

Sliding Vane Action Video

Sliding Vane Pumps

LGL3021A Pumps

Drop-In Replacement Multi-Purpose LPG & NH3 Pumps

- Drop-in replacement for competitive pumps without changing piping connections or motor drives

- Max flow rate 210 gpm (795 L/min)

- Max differential pressure 150 psi (10.34 bar)

- Self-priming, high suction capabilities enable line stripping

- Self-adjusting vanes keep performance consistency high

- UL listed

- Equipped with replaceable cavitation suppression liner, end discs, and vanes

- Standard cavitation suppression liner reduces noise, vibration and harmful effects of cavitation

- Applications:

- Bulk plant service

- Multiple cylinder filling

- Vaporizers

- Bobtail and transport loading and off-loading

LGL3021A Spec Sheet

Sliding Vane Diagram

Sliding Vane Benefits

Sliding Vane Cavitation Liner

Sliding Vane Action Video

BOMBAS DE PALETAS DESLIZANTES

BOMBAS LGL3021A

Bomba multipropósito de reemplazo directo para GLP & NH3

- Reemplazo directo para bombas de la competencia sin cambiar conexiones de tubería o motores

- Máximo rango de flujo 210 gpm (795 L/min)

- Máxima presión diferencial 150 psi (10.34 bar)

- Autocebante, alta capacidad de succión

- Paletas autoajustables, mantienen su eficiencia volumétrica

- Certificación UL

- Equipada con camisa supresora de cavitación, discos y paletas

- La camisa supresora de cavitación reduce el ruido, vibración

- Aplicaciones:

- Plantas de almacenamiento

- Llenado de cilindros

- Vaporizadores

- Carga y descarga de pipas y/o transportes

LGL3021A Spec Sheet

Sliding Vane Diagram

Sliding Vane Benefits

Sliding Vane Cavitation Liner

Sliding Vane Action Video

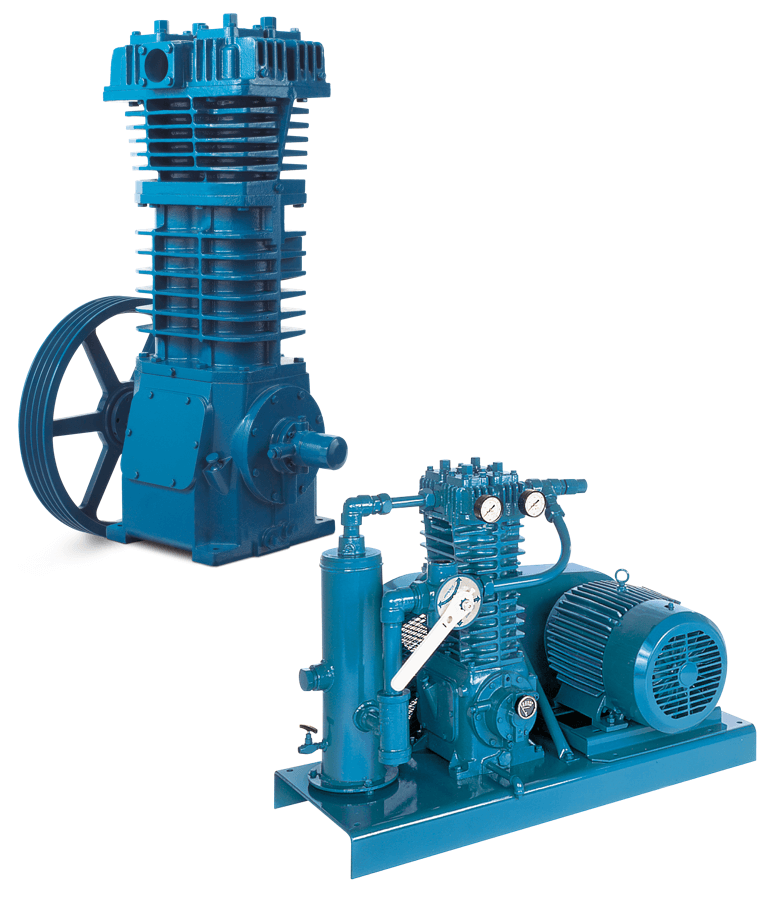

Reciprocating

Gas Compressor

LB Series

- Appropriate for use with LPG, propane, butane, anhydrous ammonia

- Durable and robust single stage, 2 cylinder compressor with 10 different models

- Piston displacement up to 125 CFM (212 m3/hr)

- Working pressure up to 350 psia (24.13 bara)

- Single, double and triple seal models available to provide superior leakage control and prevents oil contamination of the compressed gas stream

- Superior valve design

- One piece piston design

- Wear parts are thicker, larger, and less complex than competitors

- Mounting – transport mounted, and can be adapted for either direct drive or V-belt drive

- Applications:

- Liquid transfer

- Vapor recovery

LB Compressor Brochure

Transfer LPG From Underground Tanks

Cylinder Tank Evacuation

Compressor Railcar Unloading

Compressor Action Video

Vapor Recovery Video

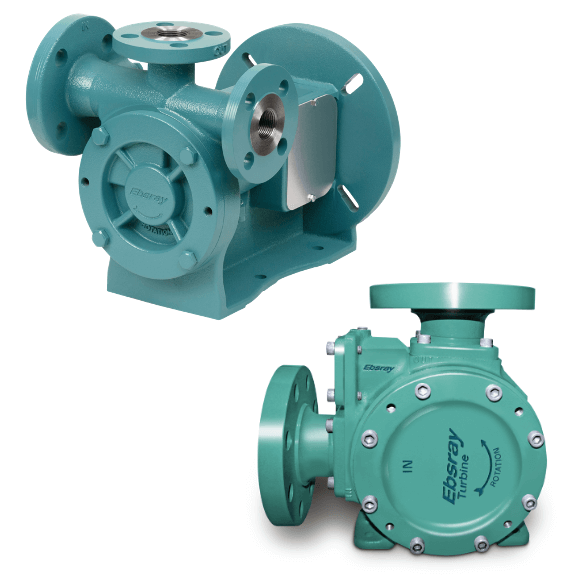

Regenerative Turbine Pumps

Ebsray RC Series

The RC Series are base-plate mounted regenerative turbine pumps ideal for dual hose and multiple dispensers in Autogas applications with above ground or underground tanks.

- Low maintenance single-stage impeller

- Quiet, smooth, pulse-free operation

- High differential-pressure capability

- Long pump life

- Three-ported design simple installation and safe operation

- Applications:

- Autogas driveway dispensing for up to four hoses

- Transfer and industrial dispensing

- Marine dispensing

- Portable tanks

- Cylinder filling

- Forklift refueling

- Direct burner or vaporizer feed

- Above ground and underground tank

RC20

- Max flow 16 gpm (62 L/min) at 60Hz & 13 gpm (48 L/min) at 50Hz

- For one hose dispensing

- Max differential pressure 145 psi (10 bar)

RC25

- Max flow 28 gpm (106 L/min) at 60Hz & 21 gpm (80 L/min) at 50Hz

- Up to 2 hose dispensing

- Max differential pressure 145 psi (10 bar)

RC40

- Up to 4 hose dispensing

- Max flow 53 gpm (200 L/min) at 60Hz & 44 gpm (165 L/min) at 50Hz

- Max differential pressure 200 psi (14 bar)

Ebsray RC Series - RC20/RC25/RC40 Brochure

Regenerative Turbine Action Video

Regenerative Turbine Technology

Autogas White Paper

Above Ground Autogas Tank Installations

Underground Autogas Tank Installations

Regenerative Turbine Pumps

Ebsray RX Series

Submersible Regenerative Turbine Pumps

The RX Series of submersible regenerative turbine pumps can be used for high-pressure pumping of Autogas from underground or above ground storage tanks.

- Single-stage regenerative turbine pumping element

- Quiet, smooth, pulse-free operation

- Submersible concept guarantees rapid priming and pressure generation

- High differential-pressure capability

- Applications:

- Autogas driveway dispensing for up to four hoses

RX10

- Up to 4 hose dispensing

- Max flow 27.91 gpm (103 L/min)

- Max differential pressure 130 psi (9 bar)

RX33

- Up to 2 hose dispensing

- Max flow 14.53 gpm (55 L/min)

- Max differential pressure 125 psi (8.6 bar)

Ebsray RX10 Product Brochure

Ebsray RX33 Product Brochure

Regenerative Turbine Action Video

Regenerative Turbine Technology

Autogas White Paper

Above Ground Autogas Tank Installations

Underground Autogas Tank Installations

Regenerative Turbine Pumps

HiFlow Series Regenerative Turbine Pumps

R80 & R82 – Base Mounted Large Volume Regenerative Turbine Pumps

- 75mm (3") inlet & discharge ports

- Operating speed range from 2,100 to 3,500 rpm

- R80 features flow rates of 150 to 500 L/min (39.6 to 132 gpm)

- R82 features flow rates of 180 to 600 L/min (47.6 to 159 gpm)

- Temperature range from -40°C to 100°C (-40°F to 212°F)

- Maximum working pressure of 30 bar (435 psi)

- Ni-Resist turbine impeller – provides unmatched durability and long operating life

- Sealed for life bearings protected from LPG ingress, and require no routine maintenance

- Balanced multi-spring carbon vs. silicon carbide mechanical seal provides years of trouble-free operational service

- Foot mounting

Ebsray HiFlow Series Product Brochure

Regenerative Turbine Action Video

Regenerative Turbine Technology

Ebsray R80/R82 Cutaway

Autogas White Paper

Regenerative Turbine Pumps

HiFlow Series Regenerative Turbine Pumps

R75 & R77 – Large Volume Truck Loading and Unloading Regenerative Turbine Pumps

- Driven by electric drive, hydraulic drive or high-speed PTO

- 3-inch (75mm) inlet ports

- 2-inch (50mm) discharge and auxiliary ports

- Features integral bypass valve set on 200 psi (14 bar) for R75

- Operating speed range from 2,100 to 3,500 rpm

- R75 features flow rates of 40 to 132 gpm (150 to 500 L/min)

- R77 features flow rates of 48 to 159 gpm (180 to 600 L/min)

- Temperature range from -40°F to 212°F (-40°C to 100°C)

- Maximum working pressure of 435 psi (30 bar)

- Ni-Resist turbine impeller – provides unmatched durability and long operating life

- Sealed for life bearings protected from LPG ingress, and require no routine maintenance

- Balanced multi-spring carbon vs. silicon carbide mechanical seal provides years of trouble-free operational service

- Flange mounted pumps

Ebsray HiFlow Series Product Brochure

Regenerative Turbine Action Video

Regenerative Turbine Technology

Ebsray R75/R77 Cutaway

Autogas White Paper

Regenerative Turbine Pumps

The regenerative turbine pump is a rotodynamic pump that combines the high discharge pressure of a positive displacement (PD) pump with the flexibility of a centrifugal pump. They excel at transferring fluids with high pressure, low flow and low viscosity while handling entrained vapors or fluids at or near their boiling point. These fluid conditions generally hamper the performance and reliability of most pump technologies, but regenerative turbine pumps maintain their efficiency in any pumping and fluid conditions, eliminating the damaging impact of cavitation and pulsation.

RC Series — RC20, RC25 & RC40 HiFlow Series — R80 & R82