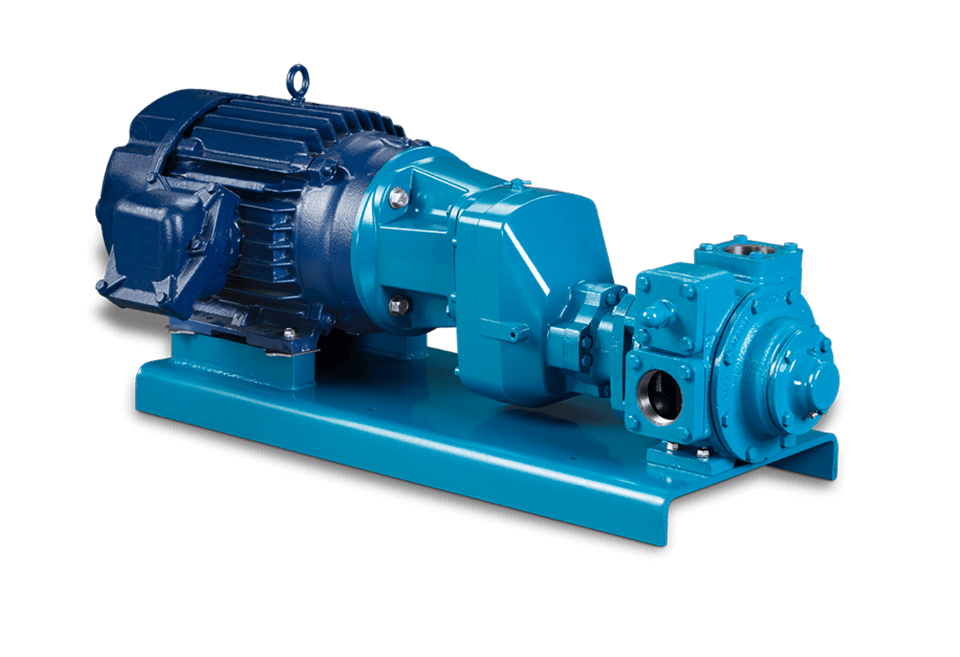

Blackmer GNX Series

Alignment-Free Reduced-Speed Heavy Duty Sliding Vane Pumps

Alignment-Free Reduced-Speed Heavy Duty Sliding Vane Pumps

- Zero-alignment points allows for maximum reliability and easy maintenance

- Zero safety guards provide safe environment for operator

Sliding Vane Movement

Replay Animation

←

- Unique sliding vane pump design self-adjusts for wear to maintain flow rates

- Sliding vane design provides sustained performance and trouble-free operation

- Excellent self-priming and dry-run capabilities

- High suction lift and line-stripping capabilities

- Viscosity flexibility: 0.2 cP to 4,250 cP using same pump

- Pressure flexibility: 0 psi – 125 psi (0 ft TDH to 290 ft TDH) without sensitivity to BEP operation

- Easy maintenance: vanes can be easily replaced without removing the pump from the piping system

- Low maintenance and low life-cycle costs

Between Bearing Design

Replay Animation

←

Sliding vane pumps use symmetrical bearing support, which supports shaft

loading on both sides:

- Results in negligible shaft deflection

- Extends seal, bearing, and shaft reliability and increases pump life

Relief Valve Design

Replay Animation

←

Sliding vane pumps offer a full port, quick opening trim valve design.

- Cracking pressure equals full recirculation pressure

- Allows for one motor size smaller than competing pumps, which have separate cracking and relief pressures

- Prevents derate of pump pressure (i.e., usable range is same as pump’s capacity)

Replay Animation

Gearbox Housing

←

Gearbox Housing

- Heavy duty bearings and shaft and oversized lube oil reservoir yields >4.0 service factor on full rated torque

- Single-stage speed reduction is ideal for desired speed ranges (200-815 rpm output speeds)

- Numerous ratio options yield speed flexibility to peg desired flow rate

X

Motor Flange

- C-face or D-flange interface between gearbox and motor holds position and eliminates need for shaft alignment

X

Pump Adaptor

- Oversized adapter attaches the gearbox to the pump head

- Proprietary hollow bore gearbox accepts standard pump shaft without a coupling

- Position held by doweled connection between pump and gearbox, eliminating need for shaft alignment. Pump will not lose alignment during operation, during maintenance, or during unit install/relocation

X

Gearbox Rotation

Replay Animation

Motor

←

Full Range of C-face Motors

- Rating: 1 HP – 50 HP (0.7 kW – 40 kW)

- Power Supply: 1-phase or 3-phase, 190/240/380/460/575 volt, 60 Hz or 50 Hz

- Inverter duty (VFD rated) for 2:1 to 10:1 constant torque turndown

- Hazardous Class: Both TEFC and Hazardous Explosion Proof Division 1

- Arrives pre-shimmed when purchased from the Blackmer factory

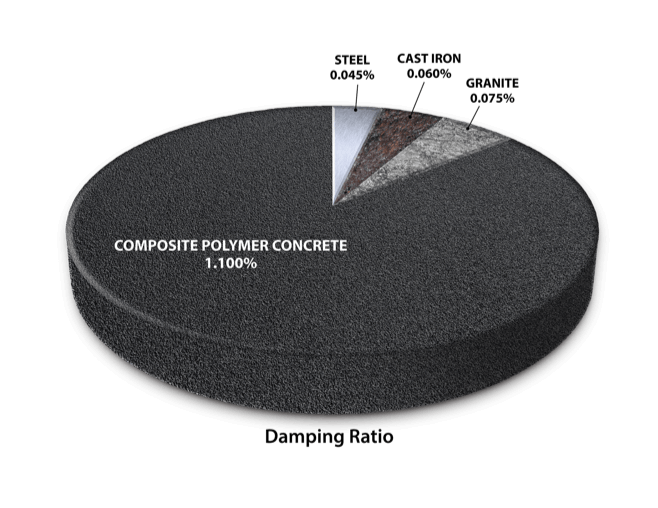

Composite Polymer Concrete BaseplateSteel Baseplate

Composite Polymer Concrete Baseplate

Corrosion Resistant:

- Will not rust or corrode

- Eliminates need for paint or expensive protective coatings

Maximum Reliability:

- 0.002" per foot flatness eliminates need for secondary machining operations and provides a lifetime level mounting surface

- 4x better vibration dampening provides reduced fatigue on rotating elements (motor, gearbox, and pump)

Steel Baseplate

- Upgraded bent steel with full length welded motor pads

- Built-in anchor holes

- Tight tolerances for machined surfaces ensure level anchoring points

←