When you're weight training, swimming or running, understanding the range of your endurance, stamina and body movement can help you reach your highest performance. It’s the same way when looking to optimize the performance of your Wilden® air-operated double-diaphragm (AODD) pumps.

AODD performance curves provide the necessary information for operators to identify a pump’s overall operating range, performance and air consumption. Understanding this information allows operators to improve the capabilities of the AODD pumps and optimize their operation. That’s why Wilden provides performance curves for all of their AODD pumps.

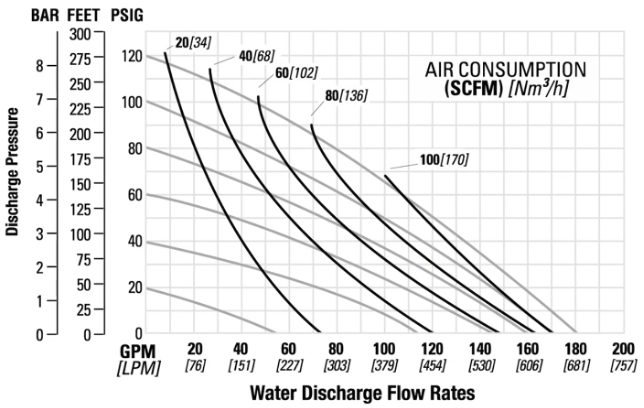

Reading and understanding an AODD performance curve involves understanding the following axes in the performance chart:

- The Horizontal Axis represents the discharge flow rates in gallons per minute or liters per minute

- The Vertical Axis represents the pressure, corresponding to air inlet and outlet pressure in psi and bar or the total head in feet

- The Gray Curved Axis represents the pump’s air inlet in psig and connects the Horizontal Axis to the Vertical Axis

- The Black Vertical Curved Line represents the air consumption of the AODD pump, measured in standard cubic feet per minute of SCFM

A diaphragm pump’s operating range is the minimum to maximum gallons, or liters, pumped per minute. This can be identified where the Horizontal Axis connects to the Gray Curved Axis.

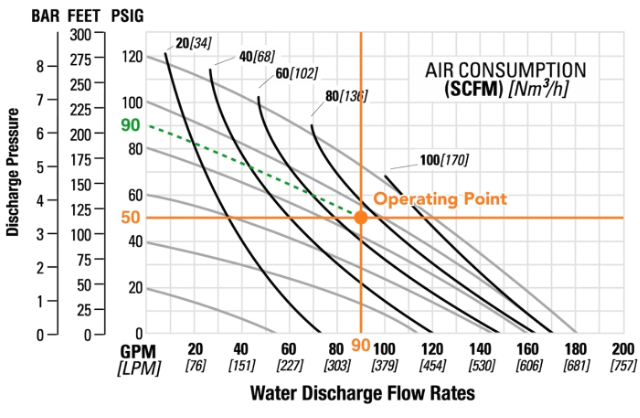

The AODD Pump Performance Curve defines the pump’s performance based on a specific operating point, utilizing the required gallons per minute (90 gpm in the example below) at a certain discharge pressure (50 psig in the example below). The operating point can then identify the required air inlet pressure needed to operate the pump by following the Gray Curved Axis (noted in green, 90 psig, in the example below).

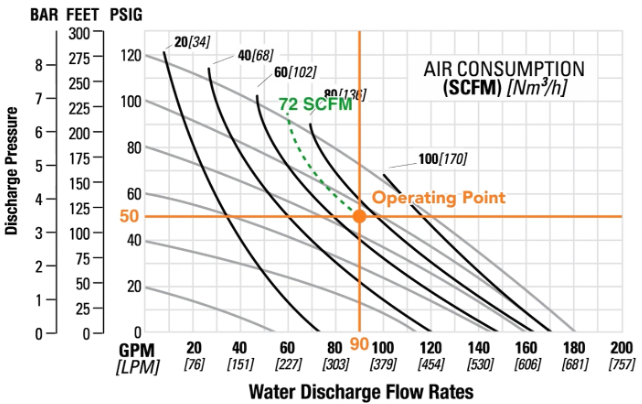

From the same operating point, the pump’s air consumption can also be identified by following the Black Vertical Curved Lines. In the example below (noted in green), following the Black Vertical Curved Lines up, which lies between 60 and 80 SCFM, you can expect the AODD pump’s air consumption to be about 72 SCFM.

Defining the air consumption can not only identify cost saving opportunities, but help size the appropriate compressor for a system.

To size the air compressor for your system based on the pump’s 72 SCFM air consumption, use the formula:

hp (horsepower) = SCFM/4.5

In this example: 72 divided by 4.5 equals 16

Because air compressors are sized in increments of 5, the air compressor size will need to be rounded up to 20 hp.

Understanding how to identify the overall operating range, performance and air consumption of an AODD pump can optimize an operation and extend the life of wear parts.

To learn more about how to read an AODD pump performance curve, watch the video: How To Read A Wilden Performance Curve