CMP Slurry and DI Water cross contamination events were disrupting operations and depressing yields at a major, multi-national semiconductor manufacturer. On a reoccurring but sporadic basis, the customer discovered CMP slurry contaminating its DI water systems or their CMP slurries supplies were inexplicably diluted. On some occasions, DI water was delivered to the platen when slurry had been requested. On other occasions, slurry was delivered when DI water was requested. Malema Sensors™ was approached for a very low flow, bi-directional flow switch that could detect and provide a warning that these events were occurring.

Challenges

Malema™ investigated and determined that the underlying problem was an intermittent by-pass leak in a three-way diverting valve that developed during certain operating conditions of the polishing tool. The three-way valve was not damaged by these events, but wafers were lost and yield was reduced.

The problem was believed to be unexpected back-flows or internal by-pass leaks through the cross connection point in the CMP polishers. Upon inspection of the three-way valve at the cross connection point, no obvious defects were observed. Clearly, the by-pass leaks resulted from operational conditions beyond the capability of the three-way valve. Various sensors – including pH, conductivity, low-flow directional & bi-directional flow switches, and flow meters – were explored in an attempt to detect these back-flows and by-pass leaks as they were occurring. While it was found possible to detect these cross contaminating back-flows and by-pass leaks, the damage was already done by the time the events were reported.

A solution was needed that prevented these by-pass or reverse flow leakages from ever occurring.

The Malema™ Interconnect Interlock Device (MIID) solves these problems.

The MIID Solution

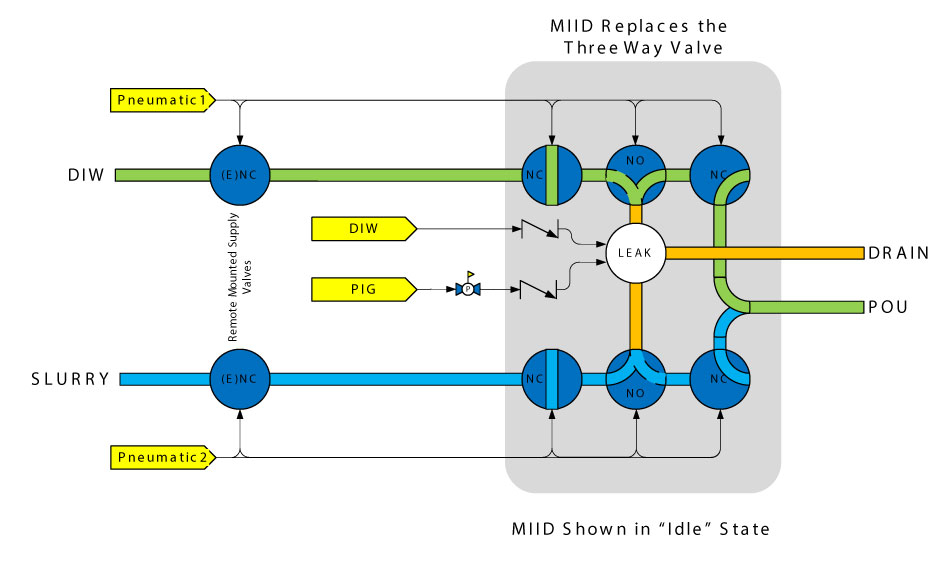

Malema Sensors™ proposed a double containment system based on the Double Block & Bleed (DB&B) arrangement used in fuel gas distribution systems. For over one hundred years, fuel gas delivery systems have needed to provide absolute shut-off of gas flow past an isolation point so that workers could service downstream facilities in a safe manner. The solution developed was the Double Block & Bleed piping arrangement (Figure 1). This clever piping arrangement anticipates leaking valves, and yet provides absolutely positive shut-off. It can be relied upon in every situation. Malema started with this DB&B philosophy and added features required to manage CMP slurries. The result is the Malema™ Interconnect Interlock Device (MIID) (Figure 2).

Figure 1 - Classic DB&B

By providing true double containment between the two liquid supplies, internal by-pass leaks and associated back flows are completely eliminated. In addition to eliminating undesired back flow events, the MIID also provides a warning signal when valves in the system begin developing by-pass leaks. From Malema™ lab testing we know that even when all the valves in a MIID are forced to leak there is still no opportunity for a by-pass leak to propagate material downstream to the POU or back upstream to the attached supply systems.

Figure 2 - MIID-1000 P&ID

Prototypes of the MIID were built, installed and the cross contamination events stopped. On April 7, 2015, Malema Engineering Corporation was awarded U.S. Patent 8,997,789 for the Malema™ Interconnect Interlock Device (MIID) By-Pass Leak Detection and Prevention system.

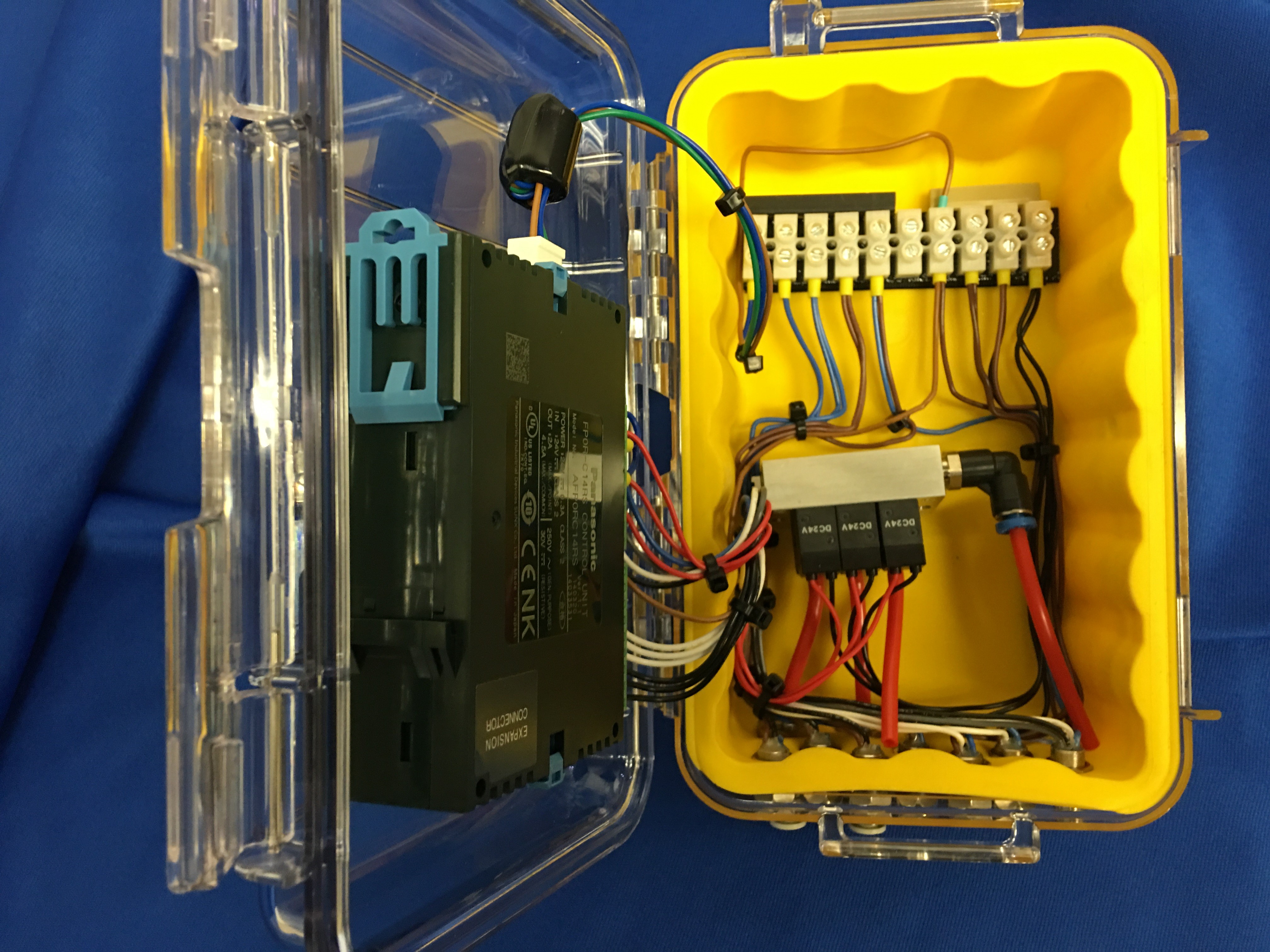

Malema™ provides multiple-MIID retrofit kits including all the materials required to upgrade the leading polishing tools. Using these kits, skilled and experienced installation teams have completed polishing tool upgrades in as little as two hours. A preprogrammed, tiny PLC in a watertight enclosure (Figure 3) ensures a simple upgrade.

Figure 3 – MIID PLC and Enclosure

The MIID upgrade is completely transparent to the host tool controller. No adjustment to the host tool software is required. Existing plumbing and pneumatic signals are repurposed to manage MIID functions. Electrical connections between the MIIDs and the PLC are fully connectorized using plug & play Turck® PicoFast® connectors. If desired, the leak warning signal generated by the MIID PLC can be attached to existing user input channels on the host polishing tool.

Results

This customer buys new polishing tools and replaces the OEM supplied three-way valve with MIIDs prior to commencing operations. For over five years, MIIDs have been POR for several technology nodes.

Due to confidentiality concerns ROI is difficult to calculate, but the loss of wafers from this cause has been eliminated and in most operations only a few wafers saved more than covers the cost of a MIID upgrade.