Cavitation can ruin internal pump components, and most pumps fail when operating under sustained cavitation, pumping liquid/vapor mixtures and carrying out poor Net Positive Suction Head (NPSH) applications.

Within a piping system, there are three susceptible locations for vapor formation: inside the supply tank, within suction piping, and inside the pump. The cause of vapor formation in a pump chamber is generally due to a greater required NPSH (NSPHr) than available NPSH (NPSHa); however, if operators only focus on NPSH, they are still ignoring two of the three potential vapor sources, the supply tank and suction pumping.

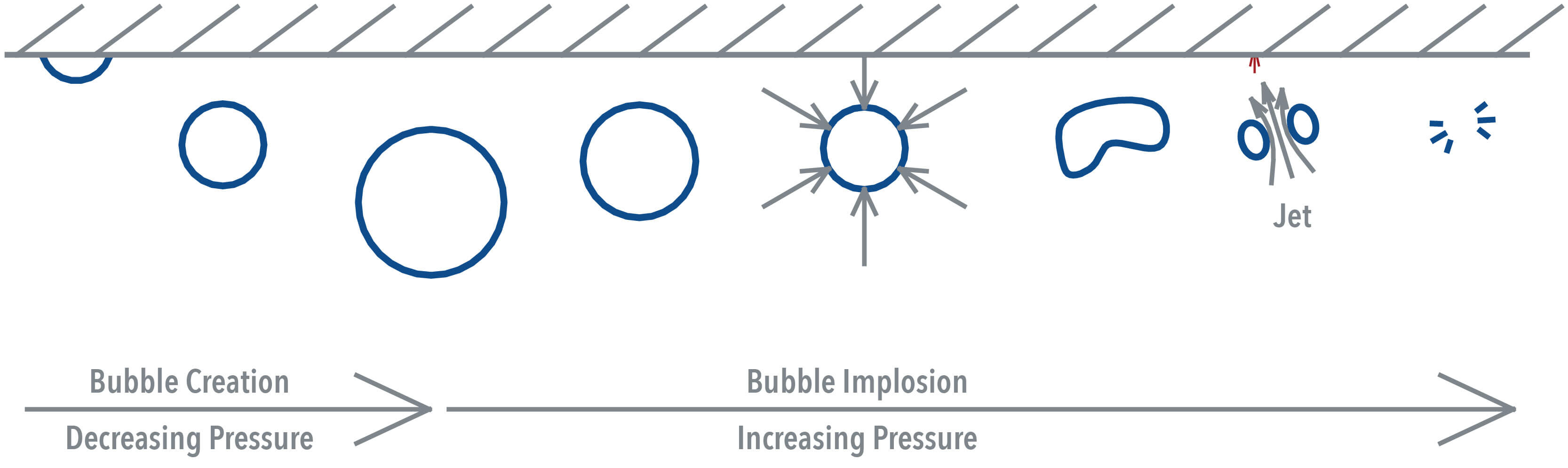

Regardless of where vapor forms, all vapor implodes within a pump’s pressure stages, producing shock waves that sound like gravel passing through piping. Shock waves from vapor implosion can impact pump, seal and inline components as frequently as 10,000 times per second in rapid, repetitive cavitation. Breakdowns, leaks, costly downtime and repairs and replacement often follow this phenomenon.

Because of its potential costs, cavitation can be a significant pain point for those transferring chemicals, solvents and hydrocarbons. Centrifugal and gear pumps often fail in the face of this phenomenon or corresponding liquid/vapor mixtures and poor NPSH applications. Standard centrifugal pumps rely on converting velocity head to pressure head, which is not possible with compressible entrained vapor, while magnetic drive centrifugal pumps rely on high surface speed ceramic bushings that can fail when exposed to non-lubricating vapor. Gear pumps are not as equipped to handle vapor and thin liquids because of the galling of internal parts and failed bushings.

Now, Blackmer® has introduced a pump solution that better neutralizes the negative effects of cavitation. MAGNES Series Sliding Vane Magnetic Drive Pumps are built upon 70 years of Blackmer expertise in developing technologies for pumping liquefied gases. This new pump series boasts capabilities to process mixtures of up to 20% vapor content while producing an effective zero NPSHr, and it is rated to receive vapor formed upstream and within the pump, addressing the areas susceptible to vapor formation. MAGNES is especially compatible with fluids that are stored in vacuum tanks and liquefied gas tanks.

While operating at a speed of just 400 rpm, MAGNES generates the same pressures and flow rates of other pumps that operate at 3,600 rpm, with no excessive heat buildup or component wear. As a true self-priming pump, MAGNES does not require pre-flooding at startup and is well-suited for continuous-duty operation. Since the pump also has no cumulative dry-run time limit, it provides confidence that a dry-run event will not result in catastrophic pump failure.

Solve pumping issues due to entrained vapors and poor inlet conditions, while staying leak-free with the low-to-zero NPSHr and cavitation and vapor mixture handling ability of MAGNES, the Sliding Vane Magnetic Drive Pump. Learn more about MAGNES at blackmer.com.