Making single-use precision pumps out of 100% recyclable materials is no easy challenge, but it is one that Quantex has been determined to achieve…

…We are therefore, very proud to announce that we can now offer Eco versions of our Low Flow Pump, Bag In Box Pump and High Flow Pump ranges, which are made from 100% recyclable materials, as well as reducing weight by nearly 12% on average, and a corresponding reduction in waste.

Achieving 100% recyclability

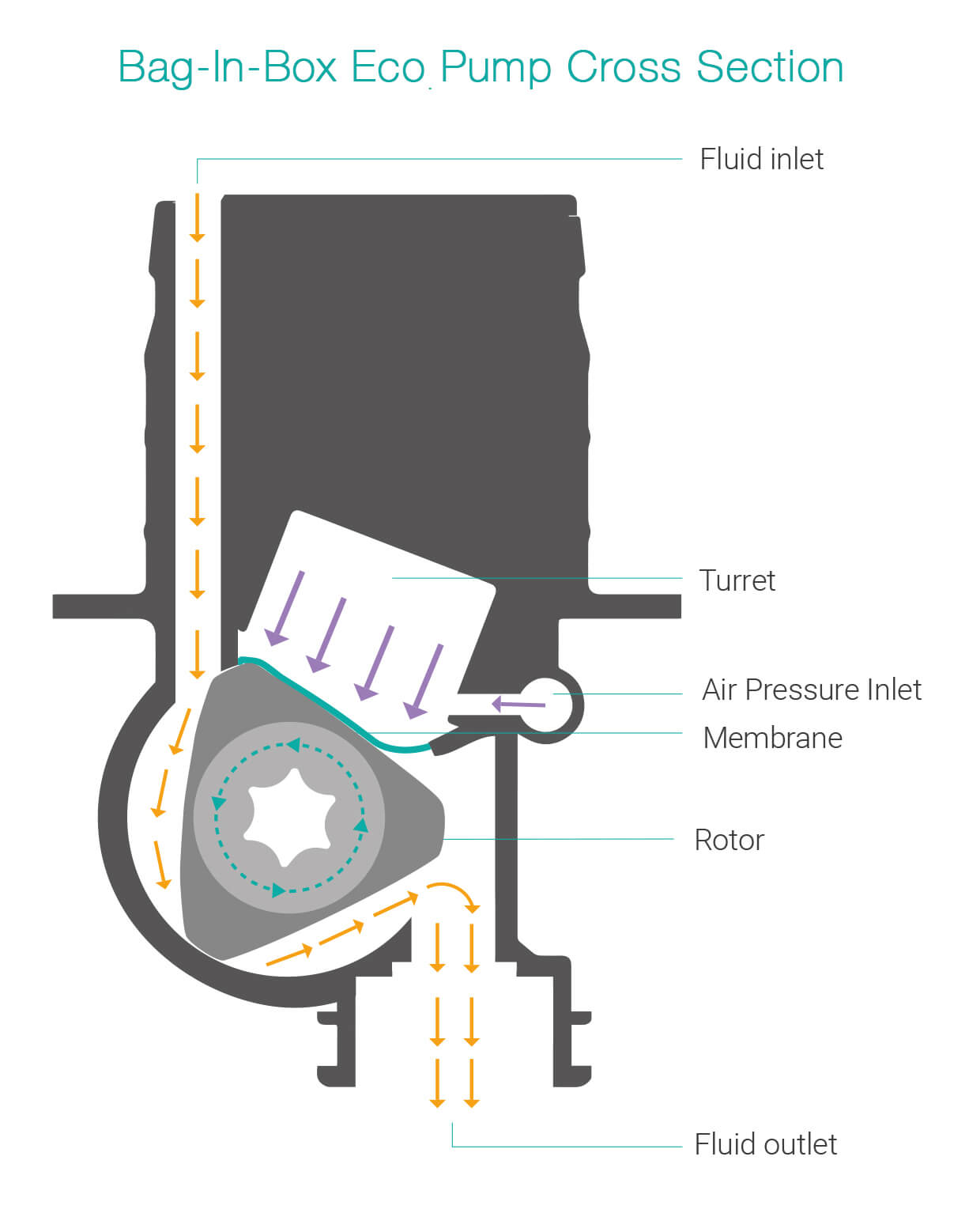

Our standard and dilution pumps contain an elastomeric spring that presses the membrane against the rotor of the pump to form a seal. This spring is made of silicone so, although some of our customers successfully recycle these pumps, it is not as straightforward as it could be: they are using grinding and flotation methods to separate the silicone from the rest of the polyolefin family of plastics. In our new Eco pumps, we have removed this silicone spring entirely and replaced it with air pressure to seal the membrane against the rotor. The new Eco Pumps’ design is an evolution of our dilution pumps. The cavity where the spring is normally housed is sealed, except for an inlet from (what was previously) the ‘dilution’ port. This port is now connected to a low-cost air pump, which is included in the enduring equipment. This applies air pressure to seal at the same time as the Eco pump starts the dispense.

We have also exchanged a small nitrile rubber lip seal for a thermoplastic elastomer material which belongs to the polyolefin family and can, therefore, go through the same recycling stream.

We are very excited to migrate this breakthrough technology into production across our range of pumps. If you would like to speak to us about our Eco Pumps and evaluation kits to drive these Eco Pumps, please email info@quantex-arc.com or call +44 (0)208 735 5880.

To keep up to date with all of our new technology releases, company news and events, join our mailing list. You will receive four newsletters per year and you can unsubscribe at any time.