Product viscosity is a very important consideration for any manufacturer or flow-control engineer who manages the dispense of thick, highly viscous liquids, but especially for those working with chocolate or confectionery-related products due to the unique and variable viscosity of chocolate.

As we previously discussed in our blog ‘How to transfer high-viscosity liquids’ the “pressure and flow rate needed to propel the produce out of its primary container and into its intended location will differ” depending on the viscosity of the liquid. In the case of melted chocolate, however, the final viscosity can vary greatly depending on the differences in production, composites, temperature and other factors. Examples of different chocolate-related food and beverage items and their approximate viscosities are noted in the below table: (Note pure water is 1.0cP).

| Product (at room temperature unless specified) | Viscosity (centipoise cP)

|

|---|

| Caramel | 400 @ 140°F |

| Chocolate | 17,000 @ 120°F |

| Fudge (hot) | 36,000 |

| Toffee | 87,000 |

| Milk | 1.2 @ 60°F |

| Corn Oil | 30 |

| Corn Syrup 41 Be | 15,000 @ 60°F |

| Glucose | 10,000 @ 100°F |

| Honey | 1,500 @ 100°F |

Chocolate starts its life from the Cacao tree. This plant will produce the cocoa beans/seeds which are then roasted and ground into a paste. The paste is then mixed with ingredients that may include milk, sugar, emulsifiers and other flavourings depending on what type of chocolate is being manufactured. The final viscosity of the chocolate depends on how the chocolate is treated, its additional ingredients and how it gets manufactured.

Multiple factors can alter the viscosity of chocolate products, these include:

- Fat content – the higher the fat content, the more viscous a product tends to be e.g it’s considered that ‘the higher the percentage of cocoa butter, the more viscous the chocolate will be’. If the first ingredient listed on a product label is cocoa butter, then the chocolate is considered more viscous as it indicates that it has a higher quantity of cocoa butter than its other ingredients. This would indicate that dark chocolate (which has a higher level of cocoa butter) is more viscous than milk chocolate or white chocolate.

- Added ingredients (flavours) – In order to make chocolate, the cocoa nibs and cocoa butter need to be mixed with other ingredients that hold their own viscosity levels, therefore altering the product’s final viscosity level.

- Emulsifiers – products with more emulsifiers tend to be less viscous as the emulsifier will aid the smoothening of chocolate.

- Degree of temper – this is the temperature needed at various stages to keep the liquid chocolate melted and at it’s best condition. If chocolate is not tempered properly, the cocoa butter crystallisation is uneven and uncontrolled, resulting in an unattractive dull looking chocolate with white streaks throughout it. If allowed to cool enough, it would harden becoming more viscous during manufacture.

- Temperature – a colder temperature significantly increases the viscosity of a product making it more solid and less smooth/runny.

- Conching time – this entails the continuous movement and displacement of the product over a prolonged period. The longer the conching process, the more viscous the chocolate will be.

How conching affects the viscosity of chocolate

When we talk about the conching process of chocolate, we’re referencing the continuous grinding, mixing, and kneading of the chocolate solution over time. During this process, the chocolate will undergo mechanical shear forces, be heated and be distributed to multiple destinations. It’s in this process that the tiny particles of solids (often cocoa, sugar, and milk) acquire a more uniform and consistent shape allowing them to be evenly coated with cocoa butter. This process will determine the viscosity of chocolate, how it flows, its textural properties and determines how the finished product will melt smoothly in the mouth.

This conching process achieves several essential objectives which can affect the viscosity of chocolate solutions.:

- Texture change – the more the chocolate solution is worked and moved, the smoother the texture. The agitation and kneading action reduce the particle size of cocoa solids and sugar, resulting in a fine, homogeneous mixture

- Evaporation – any residual moisture in the chocolate can be programmed and designed to evaporate during the conching process. This can help enhance the shelf life and stability of the final product but can make a product more viscous

- Enhanced flavour – moving the chocolate solution around allows more volatile flavours (often short-chained fatty acids and aldehydes) to evaporate whilst providing a time for the interaction between cocoa solids and cocoa butter, leading to the release of flavour compounds and the formation of desirable aromatic notes

- Physical changes – through the conching of a chocolate product, you’re promoting chemical reactions, such as acid-base reactions, oxidation, and reduction processes, which can further refine the flavour, viscosity and colour of the chocolate

- Acidity removal – by altering the chocolate through the conching process, you’re reducing the acidity of cocoa and improving its pH

Normally milk chocolate on a pure chocolate solution (e.g. a chocolate bar) is conched at around 50°C to prevent the caramelisation of the product. Should the temperature be any higher, this can cause lumps and sandiness in the mouth when eating the final product.

How Quantex pumps uniquely dispense chocolate

By using Quantex pumps, the high-level viscosity of chocolate is no longer a problem due to the advanced transfer capabilities of the pumps. They use a positive displacement rotary action, with high vacuum and high pressure capability, so the dispense or transfer of chocolate solutions can be carried out at lower temperatures than with other pump technologies. Quantex pumps are powerful enough to dispense viscous fluids across distances, including cooling areas, without damaging or curing the chocolate solution. They can even pump particulates if the chocolate has small caramel pieces or salt/sugar crystals, fruit or nut pieces.

With our Quantex pump range, the liquid chocolate can be sealed aseptically within the pack as the pump is either secured directly onto the liquid pack (see our Bag-in-Box pumps) or is attached to the primary container in-line and the pack and pump are disposed of or placed into a recycling stream at the end of the pack-life. The pump simply clips into a standard motor-drive in the fixed equipment which means that product changeovers are rapid and there is no risk of cross contamination because the product stays contained within the primary container and pump head.

This game-changing technology is perfect where chocolate or highly viscous food and beverage products need to be dispensed within a retail or food service environment. This is because it keeps the product free from air and contamination, prolonging its shelf-life and eliminates cleaning – reducing costly maintenance regimes. Having the ability to swap products in and out in seconds, without cross-contamination makes the technology ideal for reducing manufacturing downtime.

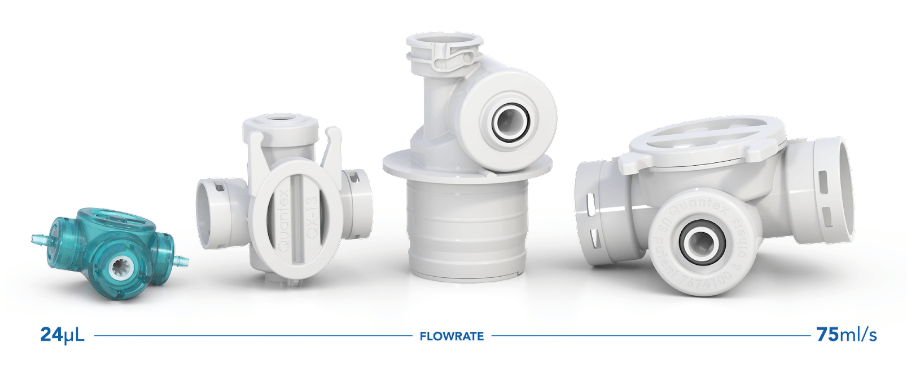

Each pump type has a range of pump configurations available, including High Pressure, In-Pump Dilution, and High-Speed, as well as a range of fittings, valves and mixers for the outlets available. Our High-Speed Eco Pumps use air pressure to activate the diaphragm and seal the pumps instead of a silicone spring, so they can run almost three times as fast as our standard or high-pressure pumps (as well as being easier to recycle).

With Quantex integrated into your primary packaging, the system deters operator from using other similar brands in your dispense equipment as the pumps hold over 100 global granted patents.

You can learn more about our pump range here:

If you’d like to learn more or discuss how a Quantex pump could work for you, please email quantex-info@psgdover.com or call +49 (2065) 89205-0.