Quantex Dilution Pumps are available in our Low Flow Pump, Bag in Box pump and High Flow Pump ranges. They mix viscous concentrates with filtered water inside the pumps in order to produce a ready-to-drink beverage into cup.

Quantex can pump cola or lemonade syrups, concentrated fruit juices, chocolate or salted caramel syrups, dairy products, coffee syrups, etc. It is possible to offer a range of flavours that can be combined to make a myriad of recipes with just a few channels. See case study “Fresh Blends Frozen Beverages IoT Platform”.

View the Bag In Box pump post mixing & dispensing mango juice

All Quantex pumps are unique in that they are so low cost to manufacture that they come attached directly to the primary pack. When a product supply is finished, the pack and pump is disposed of or recycled, and a new pack with a new pump can be inserted to replace the old one. The advantages that this system brings are:

- Increased shelf-life: Since the pumps comprise part of the liquid packs and act as instantaneous check valves, the product remains sealed from contamination during dispense which can lengthen a product’s shelf-life.

- Improved hygiene: The product only travels through the recyclable pump rather than through any parts of the fixed machine. This eliminates the need for cleaning and dismantling and soaking parts which is time-consuming and costly. For increased hygiene, an aseptic valve can easily be added to the nozzle of the pump which stops any bacterial ingress back into the pump.

- Greater flexibility: When loading a pack into a dispenser, the pump simply engages with a motor drive shaft which rotates the pumps at varying speeds. Packs are therefore easy to swap –: they simply slide in and out. This can be useful, for example, if different drinks are more popular at different times of the day. To make change-overs even simpler, RFID chips on the pumps automatically display the product’s correct graphics on interfaces and program the motor to run at the correct speeds. See case study “Linstream/Cobell Juice Machine”

- Reduced shipping weight: Quantex dilution pumps can take water out of the distribution channel by mixing higher concentrates with filtered water inside the pump to make ready-to-drink beverages at the point of dispense.

Benefits in comparison with typical post-mix dispensers:

✓ Eliminates costly peristaltic pumps

✓ No threading of tube through pump

✓ No crevices to clean

✓ Eliminates tube

✓ Eliminates tube closure (or cutting of tube)

✓ Eliminates large and costly post mix components

✓ Eliminates cross contamination

✓ Reduces cleaning regimes

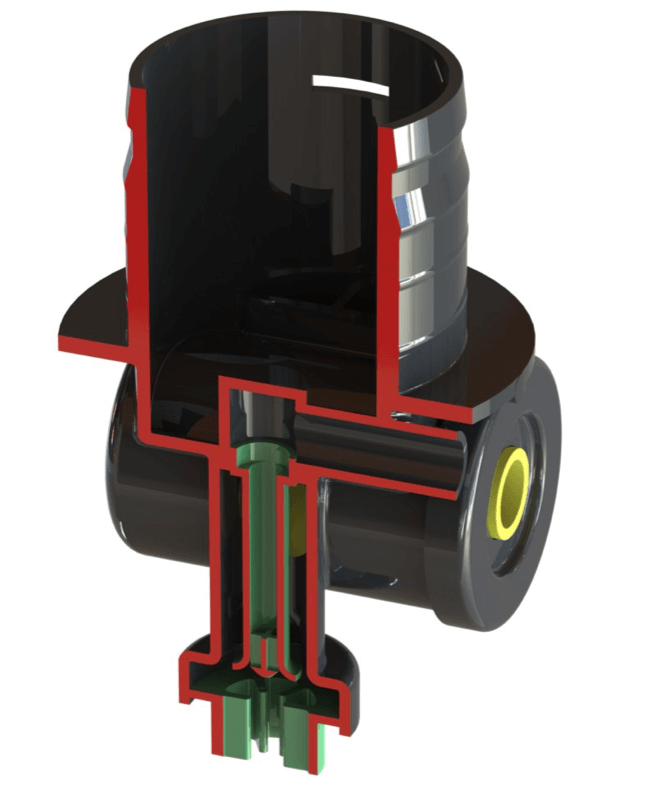

Below shows a cross-section of the QX140-DL Dilution Pump.

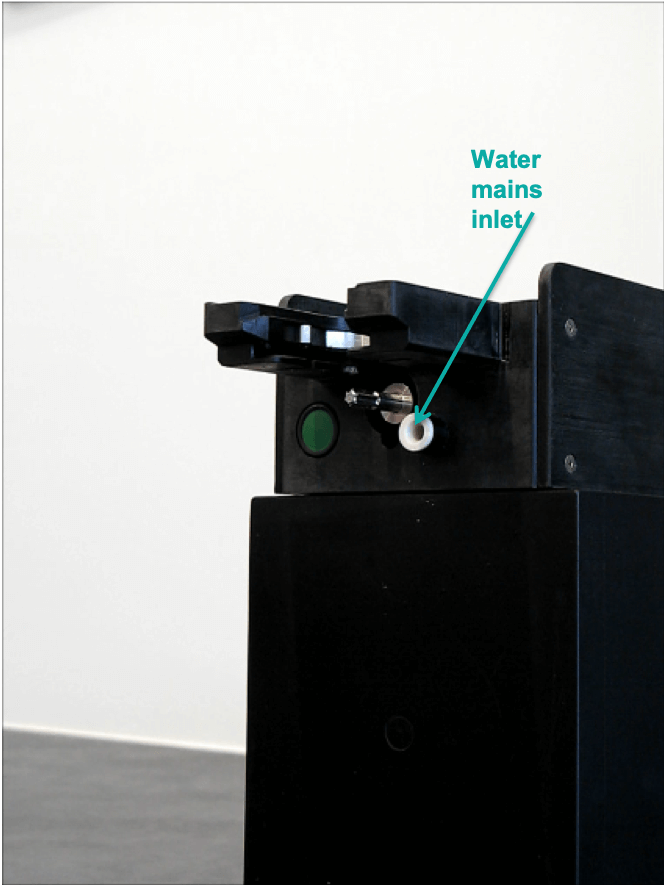

Attachment of Post-Mix Pump to Dispenser