The use of artificial intelligence (AI) and robotics is becoming more common, especially within the food and beverage industry which is undergoing a technological revolution. With this in mind, we’ve seen a rise in inquiries about how our Quantex pumps can seamlessly integrate with robotics and automatic dispensing machinery as manufacturers look for a way to drive innovation, streamline operations, enhance efficiency, and elevate the customer experience. From mass-produced ready-meals, beverage makers, drink dispensing, and fast-food chains to fine dining establishments, businesses are increasingly turning to robotics and automated dispensing.

Why Robotics and Automated Dispensing in the Food and Beverage Industry?

Robotics aren’t a new concept, the first true industrial robot was created using the Meccano model construction system in the 1930s, however, in the early 2000s, humans started to digitally program industrial robots with artificial intelligence, which paved the way for the use of robotics in industry and manufacture.

These days, robotics and automated dispensing are starting to be seamlessly integrated into many forms of manufacture, specifically within the production of food and beverage for a variety of reasons, including:

- Increased Efficiency: Robots can work tirelessly, 24/7, with minimal breaks or downtime and can significantly boost productivity.

- Improved Consistency: Robotic systems deliver precise and consistent results, ensuring that every dish or drink made will meet the predetermined quality standards.

- Enhanced Safety: Automation reduces the risk of accidents and injuries associated with repetitive tasks and handling hot surfaces.

- Cost Reduction: While initial investment costs may be higher, long-term savings can be made through reduced labour expenses and minimised error or product waste.

- Customer Satisfaction: Using robotics and automated dispensing means faster service times, consistent quality, and innovative food presentations which can lead to higher customer satisfaction and loyalty.

- Targeting KPIs and Tracking: By using a system that promotes the same response repeatedly, it makes it easier for organisations to predict what the output would be as there’s minimal risk of variation - this means KPIs and trends can be accurately tracked and monitored.

How Robotics and Automated Dispensing is Transforming Food and Beverage Dispensing

Certain industries lend themselves easily to the rise of robotics and automated dispensing - the food and beverage industry being one of them. There is a whole range of potential applications including:

- Automated Dispensing Machines: These machines are often found in convenience stores, petrol stations, and fast-food restaurants. They utilise robotics and automated dispensing by supplying a precise dispensing system to deliver a variety of food and beverage items quickly, without the need for human input.

- Robotic Cooks: Advanced robotic systems (such as the Moley, B-Air Kitchen) can prepare complex dishes, from curry, stir fry, pasta and even risotto, with remarkable precision and speed. It’s the ‘world’s first robotic chef and intelligent RFID-enhanced IoT kitchen system.’

- Food Delivery Robots: Autonomous robots are being deployed to deliver food directly to customers, as operated in Milton Keynes by Starship Technologies. They have streamlined the delivery process and reduced labor costs.

- Entertainment: Some restaurants and bars have started to ‘employ’ automated robotic bartenders, mainly as an aesthetic and to provide an additional layer of entertainment for their patrons. These bartenders can mix pre-set qualities of drink, mix and serve accurately.

- Agriculture: Robots can plant, identify, and sort seeds. They can also assess crops and their habitats for disease, pests, or yield, and in some cases, provide a remedy to a potential problem e.g. spraying plants with pesticides should greenflies be discovered.

- Food and Drink Packaging: When it comes to speed, efficiency and accuracy, robotics and automation dispensing machines are perfect - they can open, fill or dose, pack, seal, and label packages within seconds and at the ease of a button.

- Food Sanitation, Preparation and Processing: Especially within the food and beverage industry, sanitation of the product and equipment takes top priority to ensure the cleanliness and quality of the product. Robots and automated dispensing machines are being used as they can endure harsher environments than humans (such as staying within cold rooms where bacteria and infection can’t survive for prolonged periods). By guaranteeing efficient and accurate dosing, robotics and automated dispensing ensure any food and beverage served is consistently at the correct measurement.

The Role of Quantex Pumps in Automated Dispensing

Quantex pumps are already a critical component for many automated dispensing machines, including the Linstream/Cobell Juice Machine, Freshblends self-serve frozen beverages platform and can easily handle concentrates for post-mix soft and alcoholic drink dispensing machines.

Pumps without an integrated Quantex pump, however, often come with multiple pain points due to the upkeep required of the robotics and automated dispensing machines themselves as discussed in our blog ‘Top 10 Business Benefits of Refillable Drinks and Bulk-refill’.

When it comes to robotics and automated dispensing, Quantex can take things to the next level and help keep environments clean, aseptic and mess-free. By utilising a lightweight and compact Quantex pump, such as the Bag-in-Box, which is designed to be attached to the liquid packaging, manufacturers can also save valuable time and costs by reducing maintenance downtime and potential spills.

Working in a similar way to a Vitop tap used on a bag-in-box of wine, the Bag-in-Box range of Quantex pumps can directly replace this tap as it carries the same connection fitting – and, instead of pressing the tap and letting the product dribble out using gravity, the pumps are swiftly clicked into a small motor drive which doses the product accurately at various flowrates, with high vacuum and self-priming. This means that when the pack is emptied, it can be rapidly swapped in and out without the risk of spills, product wastage and technical training. When the new pack is in place, robots and automated dispensing machinery can then manage this product flow and be programmed to run as required. As the liquid product is housed securely within the pack, it remains sealed to external substances and minimises the risk of spills between pack changeovers. Quantex’s high vacuum capability also means that it draws out every last drop so there’s less wastage. And thanks to the reverse cycling capability of Quantex pumps, they can suck product back in at the end of each dispense which is how drips and cross-contamination are prevented.

As the liquid product is housed securely within the pack, it remains sealed to external substances and minimises the risk of spills between pack changeovers. Quantex’s high vacuum capability also means that it draws out every last drop so there’s less wastage. And thanks to the reverse cycling capability of Quantex pumps, they can suck product back in at the end of each dispense which is how drips and cross-contamination are prevented.

With only a standard motor drive and motor controller required, dispensing machinery can be highly compact, saving valuable space. And with such an easy-to-use system, no cleaning, maintenance or calibration are required. The Quantex pumps help to keep the liquid optimally hygienic and air-free, reducing the risk of product spoiling/ congealing.

Managing Thick Viscous Products in the Food and Beverage Industry

Quantex pumps are particularly recognised for their ability to handle highly viscous solutions (including melted chocolate, condiments (i.e. ketchup and mayonnaise) and yoghurt) In fact, the Quantex QX25-HP pump can pull an impressive -7 psig vacuum and revolutionises the positioning of the disposable pump in relation to the liquid packs (the pump can often be positioned above, below, to the side) keeping the same level of viscous suction power.

The video below shows Quantex dispensing extremely viscous Nivea cream.

Here is a Quantex Bag In Box Eco High-Speed Pump dispensing viscous Ketchup and Mayonnaise.

Mixing Concentrates with Water In-pump

One of the features we see many food and beverage suppliers enjoy is the fact that, with Quantex pumps, you can dilute in-pump. This enables brands to supply their product to retailers in a higher concentration saving money on shipping costs by taking water out of the distribution channel. For drinks dispensing, gone are the days when only water could be dispensed; Quantex pumps allow consumers to add a variety of enhancements including liquid minerals, soda flavourings, syrups, coffee, milk varieties, chocolate, flavouring etc). These added options open up the market for many businesses and create a chance for them to increase their ROI, as well as help their environmental measures.

One Pump, Providing Multiple Options

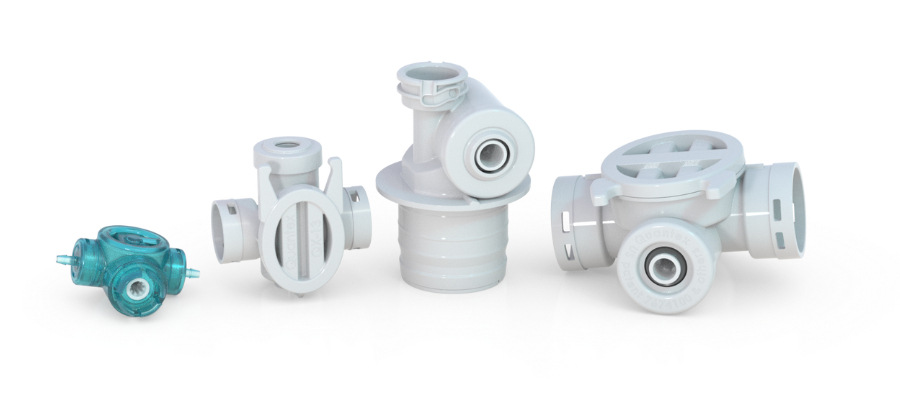

The range of Quantex pumps comes in a variety of sizes and flow rates depending on the application:

The Future of the Foodservice

As technology continues to advance, we can expect to see even more innovative applications of robotics and automated dispensing within the food and beverage industry. From fully automated kitchens to personalised dining experiences and consumer-controlled dosing, the possibilities are endless. By embracing automation and leveraging advanced technologies like Quantex pumps, businesses can stay ahead of the curve and deliver exceptional food, drinks and service.

To learn more about our pump range, please choose from the following options:

If you’d like to discuss how a Quantex pump could work for you, please email quantex-info@psgdover.com or call +49 (2065) 89205-0.